It’s easy to underestimate the amount of printed glass we use every day. This is because printing on windows, mobile phones or containers often has a functional rather than an aesthetic purpose. However, new technologies have revolutionised and expanded the possibilities for printing this incredible material. A new chapter is truly being written in the history of glass, which for more than a century has been making its mark not only in the spaces we live in, but also in printing houses.

From screen printing to digital printing with ceramic inks

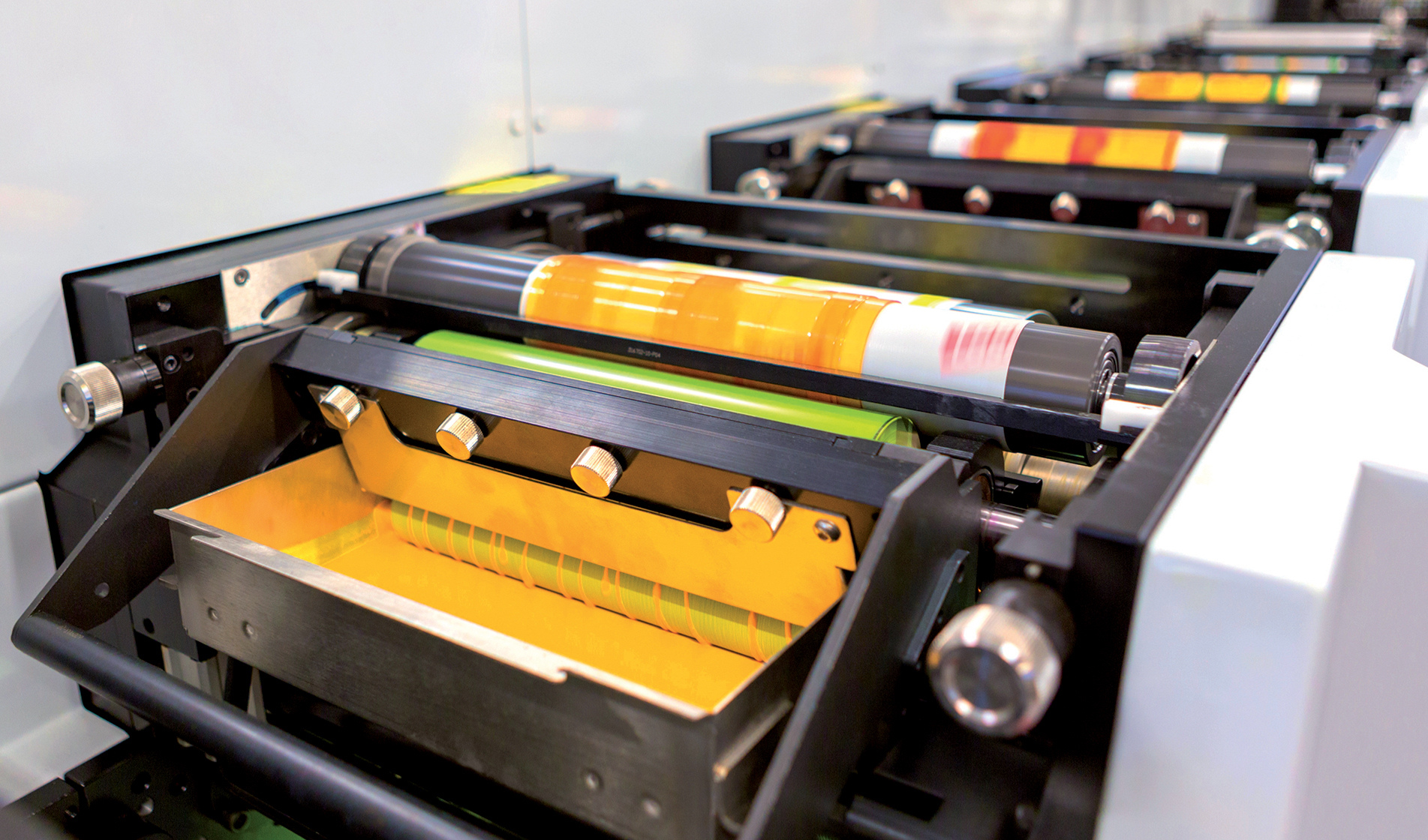

As with other sectors, digital printing has led to a revolution in the processes and production of decorated glass. Now companies can effectively respond to the need for flexibility, fast turnaround and extreme product customisation, reducing the high up-front costs of screen printing frame production. But it is the ceramic inks that have changed the way we think about printed glass. Today, printing is no longer done at the end of the project, but as part of the glass processing flow. With techniques such as screen printing or the use of UV inks, the process takes place on the plate essentially as a finished product. With ceramic inks, printing is interposed between the production of float glass and subsequent operations such as tempering, laminating or coating. This is because ceramic inks, once printed on the glassy surface, have to undergo the same heat treatment as glass, during which they literally fuse with the plate. The design becomes one with the molecular structure of the glass, completely indelible and linked to the life cycle of the product. What does this mean? That printing over time will follow all the changes and wear of the glass and not those of the printing materials.

The latest trends in glass packaging

When it comes to packaging, printing directly onto glass is a decision that can be influenced by a number of factors, not least the positioning of the products. For this reason, it is a technique that is often chosen at the top of the beverage world, especially for spirits, but not only: other product categories are also moving away from paper labels to explore the full potential of direct printing on glass.

In the world of spirits, it is important to start from two main categories when outlining trends: mixology, which is made up of spirits used to prepare cocktails, and luxury, which are spirits drunk in their purest form, and which often become collectors' items. Both share an intense R&D activity, but differ in their positioning and target audience. In mixology, the search for uniqueness is fundamental for an aesthetic impact on the shelf, an attractive design and recognition in the market: basically, the product is not valuable in itself, but is chosen on the basis of its packaging. In terms of printing, this is achieved through the wise use of colour, which must "jump off the shelf" - and it is usually never a single colour, ranging from 4 to the infinite chromatic possibilities of digital printing - gradient effects, gloss-matt contrasts, masking, textured and embossed prints, even with the "glass on glass" effect.

In Luxury, the keywords are uniqueness and elegance, exclusive design, rarity and perfectionism in design, centrality of the message. The bottles need to be harmonious and precious, and are often given as important gifts or are even kept in a safe; the message is always based on the brand's heritage. R&D is not lacking just because the aesthetics are more "classic", but on the contrary, it is focused on finding suppliers capable of satisfying the demands for excellence. The choice of printing is based on the search for exclusiveness, the use of thick foils, precious metals and polymaterial applications such as resins, Swarovski crystals and metal alloys such as Zamac, so that, as in the case of mixology, the combination of visual and tactile effects is fundamental. Beyond these specificities, there may be more general trends: the search for shapes and special effects such as glitter, watermarks, tone-on-tone and, of course, sustainability.

.png)