The converting world is facing significant challenges, the outcomes of which could lead to profound changes in the industry. We tried to identify some of these with the help of some of the exhibitors at Print4All - Bimec, BST eltromat Italia, RE, Uteco.

The first is sustainability, which cuts across practically the entire industrial world. A challenge that encompasses multiple areas (environment, energy, economics, social sustainability, ...) and concerns many different aspects (processes, technologies, materials, ...). As they point out at Re, 'in materials we are seeing an evolution towards recyclable and compostable solutions driven by current regulations, as well as attempts to use increasingly lighter materials without losing strength'. A concept also emphasised by BST eltromat Italia, which describes how 'the flexible packaging industry is moving towards more sustainable materials, such as functional mono-materials and the use of recycled plastics, to meet environmental regulations and consumer demands'. It is worth highlighting that regulatory obligations are indeed a driver of change, but this change is also propelled by customers and their demand for products made with a different level of attention compared to just a few decades ago.

Uteco, on the other hand, places the emphasis on the more technological aspects of the change that the converting world is experiencing, stating that 'today the market demands sustainability, automation, connectivity and advanced services. Converters operate in an environment where speed, responsiveness and adaptability are crucial'. For a long time, machine and system builders have been focusing heavily on concepts such as automation, efficiency, high productivity, flexibility and, more recently, the use of artificial intelligence to minimise production problems and bottlenecks. All concepts also supported by Bimec: "In the converting industry, automation and ergonomics are playing an increasingly central role in the choice of machinery. Converters are looking for advanced, intuitive and automated solutions that can simplify operations, reduce human error and minimise downtime”. For his part, Re emphasises that 'with regard to plant efficiency, perhaps the most sought-after aspect today, increasingly high-performance and automated production processes are more crucial than ever', and BST, a specialist in control systems, expresses a similar opinion: "The digitisation of processes is indeed fundamental for workflow optimisation," adding that "the introduction of AI in inspection systems allows for a more accurate classification of faults, improving the quality of the end product and facilitating the use of the tools available to operators.

Commenting on the importance of increasingly high-performance technologies, Re also highlights another trend, namely that of a "quest for ever greater customisation of packaging and end products, which, thanks to new printing and cutting technologies, allows products to be differentiated and enhances the customer experience. This means the converter having to manage ever smaller print runs while battling with competitive pricing demands. To cope with this new trend, having increasingly flexible and automated plants is vital.

What we will find at Print4All in response to these changes

During the exhibition, at the stands, visitors will be able to discover multiple ways of responding to the challenges we have just mentioned, where all the technologies needed to keep up with - and anticipate- the times will be on display.

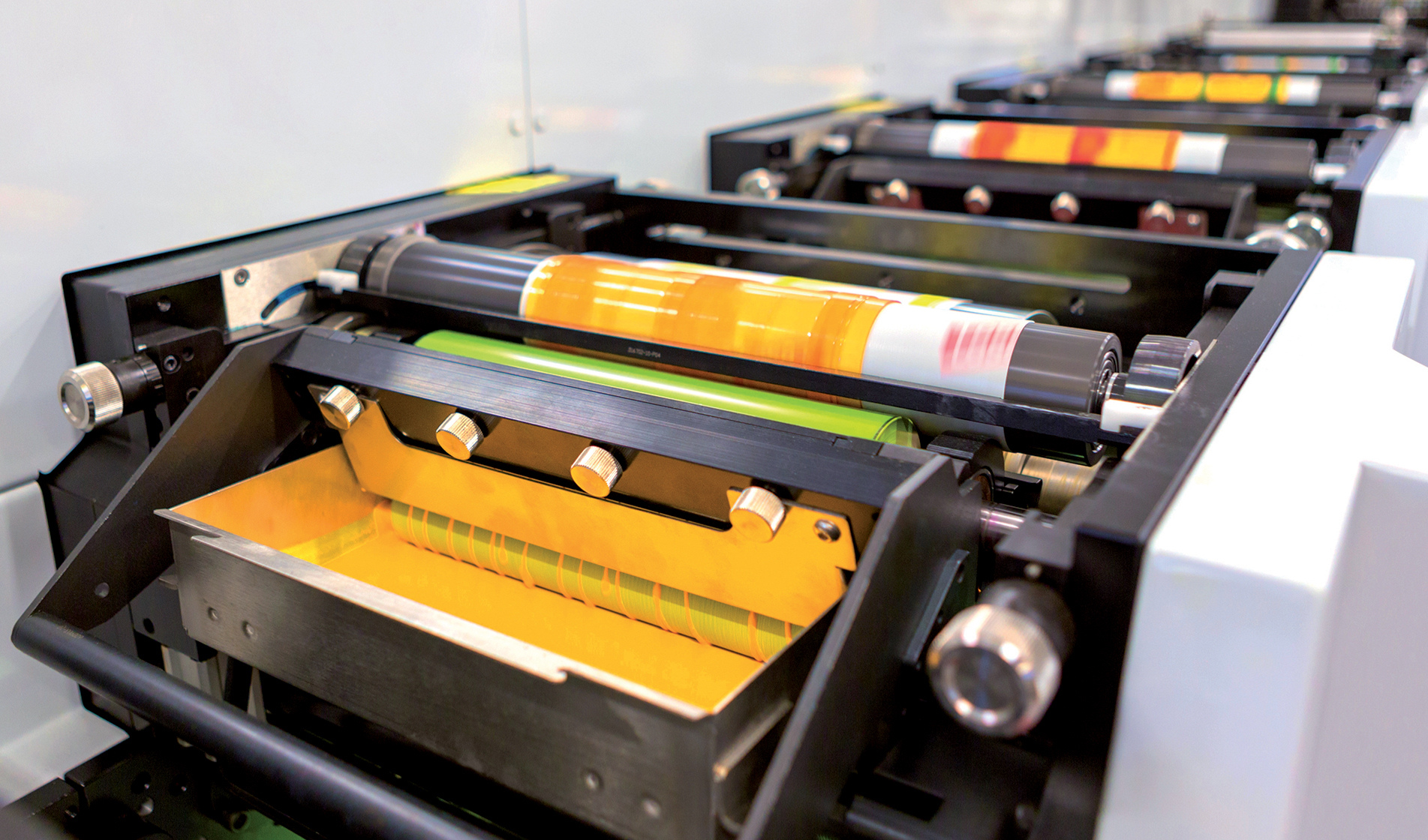

The latest innovations developed in recent months, aimed at perfecting the design and functionalities of the rewinding slitter range will be in the spotlight at the Bimec stand..

BST eltromat Italia will present state-of-the-art solutions to optimise every step of the process, from raw material production to final quality control. These will include surface inspection systems such as IPQ Surface, classic video inspection and print inspection tools (including Powerscope, ProView, IPQ View and IPQ Check, also available in a Digital version), the innovative CLS CAM100 and CAM200 alignment sensors for coating, laminating and slitting applications, the Tubescan and Tubescan XL print inspection systems, designed for optimal integration on slitting and rewinding machines, and, finally, the new version of IPQ Surface CSL, designed for Cold Seal and Windowing inspection in packaging materials.

Visitors to the Re stand will be able to discover the company's entire range of solutions, equipped with the latest improvements and adaptations to the most advanced technologies for process automation, once again underlining the vital importance of automation, which is needed to stand out in an increasingly competitive market.

Uteco will focus on sustainability, with Active Pack, the patented technology for flexo machines that reduces energy consumption and material waste by up to 50%, the only technology ESG certified for Industry 5.0; on flexibility and productivity, thanks to the OnyxOMNIA, the only FlexoDigital machine on the market, which combines central drum flexo with wide-web digital printing for high print volumes; and on connectivity, with HMI Polaris, an intuitive and user-friendly interface, and the Luna app, for smart remote monitoring.