As we approach Print4All 2025, we asked Pat McGrew, who we met at the recent Print4All conference, to share her perspective as an international industry analyst on current and near-future trends in technological solutions for the world of printing and converting. Through a series of innovations, Pat explored some existing trends and revealed other, more original ones.

The most talked-about innovation in the world of printing is undoubtedly the introduction of artificial intelligence, which McGrew says we should not expect to see as a recognisable entity, but rather hidden, i.e. embedded in the various platforms, be they software, presses, converting systems or finishing solutions. The processing power offered by AI allows for greater accuracy and speed, as well as easier interaction between the operator and the machine, with consequent benefits in terms of efficiency. But it is not only in machines that AI can make its contribution, we have recently seen interesting applications from a software point of view in all phases of production: from well-known design creation platforms to prepress, packaging production and quality control.

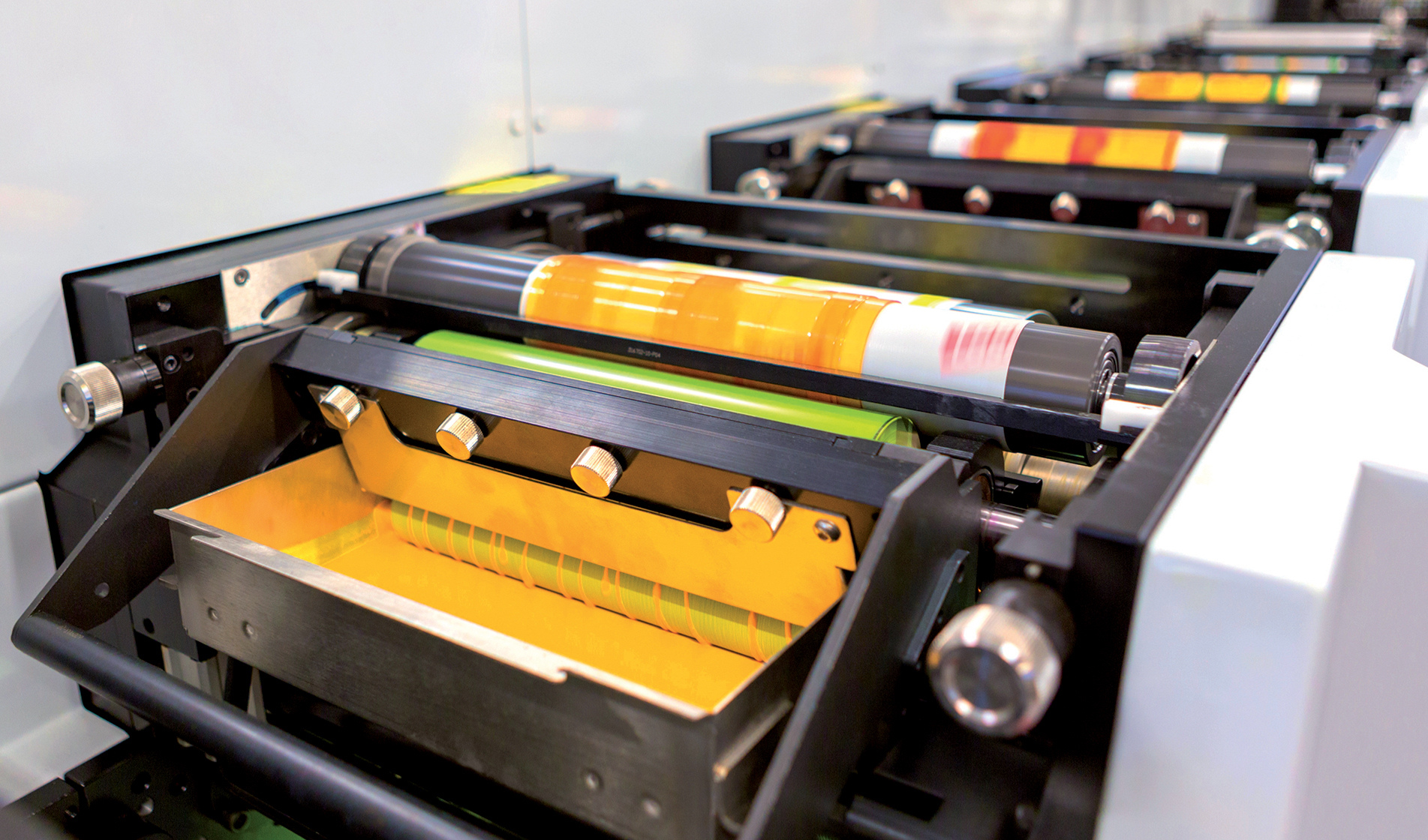

Automation is certainly a hot topic that we see in the claims of printing and converting technology suppliers. This concept certainly goes hand in hand with artificial intelligence, but also with the development of end-to-end solutions, where the various players are working increasingly closely together to develop production lines capable of offering a flow from prepress to the finished product. We are seeing it in packaging with lines for the production of corrugated cardboard boxes: from digital die cutting with automatic format change to printing, but increasingly in the label, book and even commercial printing markets.

The cobots - collaborative robots - that every manufacturer now offers are an integral part of this smartfactory, where the operator not only interacts with increasingly intelligent printing systems, but is also called upon to adopt the most extreme form of cooperation, that is to say, with truly different "colleagues", because they are machines, and they are most definitely precise and unrelenting.

Customisation remains a major trend: It is no longer just about variable data in print, but also about book formats, tools and advanced digital finishing.

Digitalisation is the other key word we have been hearing for some time. However, Pat pointed out that no standard definition can be given for this concept. Each vendor has their own interpretation and application of this concept, depending on where they are in the supply chain and the application they produce. In some cases, digitisation means connectivity, in others it means digitising the workflow, and in still others it has to do with the much-discussed concept of Industry 4.0.

All this means that machines - whether digital, offset, flexo or hybrid - are becoming more precise, more efficient and more automated. But what about software? Even in this area, evolution is leading to the development of real data-driven platforms and portals. No longer just MIS, ERP or workflow, but management systems for everything from design to logistics. In parallel, many of the workflows and software have been redesigned to be cloud native.

This development opens up a scenario where it is possible to design a T-shirt in America, print it in Belgium and wear it in Italy, as Pat McGrew did at the Print4All conference.